Vibratory Sieve Shaker ANALYSETTE 3 SPARTAN

The little sister of the ANALYSETTE 3 PRO for all typical sieving tasks in the laboratory with optical adjustment of the amplitude on the running instrument. Complete with the practical FRITSCH sieve stack tensioning system EASYTWIST and the possibility of automatic evaluation of the sieve analysis using the extensive FRITSCH evaluation software AUTOSIEVE.

The ANALYSETTE 3 SPARTAN is also suitable for quantitative particle size analysis of solids and suspensions of all kinds through dry or wet sieving with woven test sieves.

It is convertible into a micro mill for fine comminution of dry laboratory samples or solids in suspensions and for homogenisation of emulsions or pastes.

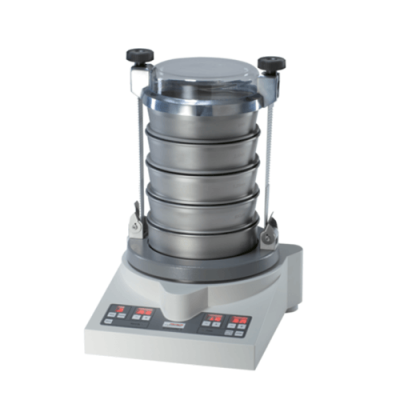

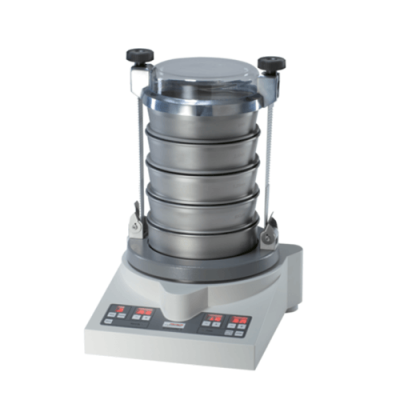

The ANALYSETTE 3 is a “shaking sieve” system in the classic sense in which an electromagnetic drive causes the sieves to oscillate in a vertical direction. The material to be sieved is periodically propelled upward off the sieve fabric and forced through the mesh of the attached test sieve as it falls back down.

Vibratory Sieve Shaker ANALYSETTE 3 SPARTAN

Features

- Automatic sieve analysis with sieve evaluation software AUTOSIEVE

- Quick conversion to Vibratory Micro Mill PULVERISETTE 0

- Exact entry of the sieving time via a precise digital timer

- Manual adjustment of the amplitude during sieving

- Display of the amplitude during sieving

- Ergonomically installed robust soft touchpad

- EASYTWIST sieve stack tensioner with steel-reinforced plastic bands is included

- Electric, easy-to-use sieve stack tensioning system TorqueMaster

- Optimum power consumption prevents warming up of the sieving system

- Up to 10 test sieves can be used simultaneously per working cycle – allowing up to 5 sieving operations to be performed at the same time

specifications

| Method of analysis | sieving |

|---|---|

| Sieving action | two-dimensional |

| Dry sieving | |

| Measuring range | 20 µm – 63 mm* |

| Max. sample quantity approx. | for sieves < 63 mm: up to 2 kg*for sieves < 100 µm: up to 100 g* |

| Sieving time approx. | 3 – 20 min* |

| Wet sieving | |

| Measuring range | 20 µm – 10 mm |

| Max. sample quantity approx. | 20 – 100 g* |

| Sieving time approx. | 3 – 10 min* |

| Further details | |

| Working principle | pressure |

| Sieve diameters | 100 mm, 200 mm or 8″ |

| Max. number of sieves per sieve stack | 10 (50 mm height), 16 (25 mm height) |

| Max. weight of sieve stack | 3kg |

| Max. height of sieve stack | 550 mm |

| Amplitude | 0.5 – 3 mm |

| Amplitude control | manual |

| Automatic sieve analysis with evaluation software AUTOSIEVE | yes |

| Convertible to Vibratory Micro Mill PULVERISETTE 0 | yes |

| Electrical details | 100-240 V/1~ 50-60 Hz, 50-60 Hz, 50 Watt |

| Emission sound pressure level at the workplace according to DIN EN ISO 3746 (depending on the material to be sieved and instrument configuration) | Approx. LpAd = 63 dB |

| Weight | 21 kg |

| Dimensions (W x D x H) | bench top instrument 37 x 40 x 20 cm |

Manufacturers

show DATA — DO NOT CHANGE ID–

Industries

show DATA — DO NOT CHANGE ID–

Methods

show DATA — DO NOT CHANGE ID–

Spares and accessories for ANALYSETTE 3 SPARTAN

ACCESSORIES FOR DRY SIEVING

For observation of the sieving process, sieve clamping lids made of plexiglas are available for FRITSCH test sieves of 100 mm or 200 mm/8“ diameter. You also receive a clamping lid made of POM plastic (without window) to sieve materials for which metallic contamination must be avoided. Also available are corresponding sieve pans and sieves made of plastic. Sieve pans and interposed sieve pans for multiple sieving operations in a single process are available in stainless steel for all sieve sizes.

ACCESSORIES FOR WET SIEVING

During wet sieving with test sieves (200 mm/8“), the specially developed clamping lid with 2 rotation nozzles ensures an uniform spraying of the sieving material from above and an optimal sieving effect. Special interposed sieving rings with three nozzles are available for simultaneous spraying of the top and bottom sieves. A sieve clamping lid of plexiglas with 1 nozzle is also offered for wet sieving with 100 mm test sieves. The corresponding sieve pans with outlet are available for all sieve sizes. To prevent the occurrence of air cushions during wet sieving with test sieves < 100 µm FRITSCH offers special venting rings.

DUST EXHAUST SYSTEM

We offer the perfect dust exhaust and accessories with integrated channels for dust-free operation, simply connect the dust exhaust system and control it directly using the start and stop button on the instrument. The button lights up in green when the dust exhaust system is ready for operation.

TEST SIEVES MADE OF STAINLESS STEEL, 8″ DIA., 2″ HEIGHT ACCORDING TO ASTM E11 MESH

For dry and wet sieving with mesh widths from 20 μm to 63 mm: especially light, robust and manufactured in high quality. Highly alloyed stainless steel protects against corrosion and simplifies cleaning. Groove-free mesh transitions prevent contamination of the sieving material. Every sieve is laser-engraved, optically measured and delivered with a compliance certificate.

CERTIFICATION

For certification of the ANALYSETTE 3 PRO as an inspection instrument, a 3.1 EN 10204 inspection certificate as well as a form for IQ/OQ documentation are available. A 3.1 EN 10204 inspection certificate is also offered for FRITSCH test sieves in accordance with ISO 3310-1.

SIEVING ACCESSORIES

TEST SIEVES MADE OF STAINLESS STEEL, 200 MM DIAMETER, 50 MM HIGH ACCORDING TO ISO 3310-1

For dry and wet sieving with mesh widths from 20 μm to 63 mm: especially light, robust and manufactured in high quality. Highly alloyed stainless steel protects against corrosion and simplifies cleaning. Groove-free mesh transitions prevent contamination of the sieving material. Every sieve is laser-engraved, optically measured and delivered with a compliance certificate.