Nitinol is nontoxic and does not promote genotoxicity, thus making it widely suitable for long-term medical implants.

The super-elastic properties of Nitinol coupled with its excellent biocompatibility means it has been the metal alloy of choice for demanding medical applications since the late 1980s.

Early medical uses of Nitinol include bone anchoring, tumor localization of specific cancers, and filter implants to trap and manage blood clotting. It is now widely adopted, with growing use, in minimally invasive surgery and dentistry.

The expected market growth for Nitinol in the medical market is expected to grow at over 9% CAGR, driven by improved therapy of chronic diseases and a preference for minimally invasive procedures. Nitinol is well suited to meet these needs.

Stents as an alternative to open surgery

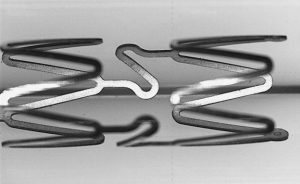

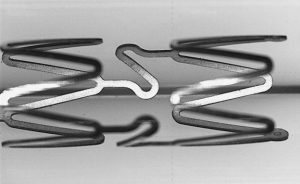

Stents made from Nitinol are used to reinforce strictures within various ducts and canals of the human body caused by trauma or chronic medical conditions.

The use of stents negates any need to perform grafts or bypass surgery which makes it a highly desirable alternative to open surgery, where risks of secondary infection are higher.

Minimal thermal impact

Ultrafast lasers are a natural choice to machine Nitinol stents and are widely used for this purpose. The near-diffraction-limited optical beam delivery yields a focused spot size optimized to machine small features. The short pulse dynamics of ultrafast lasers machine the Nitinol with minimal thermal stress or damage to the substrate.

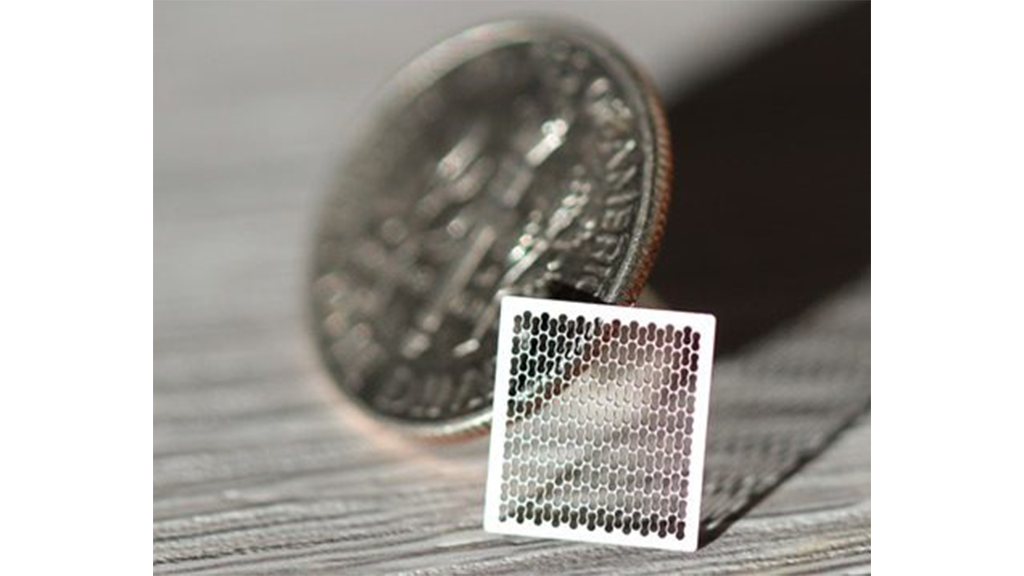

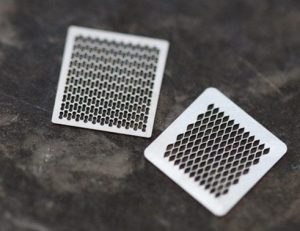

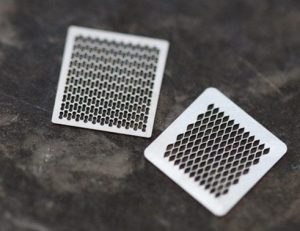

The test piece to the left shows the result of machining Nitinol with feature sizes consistent with an arterial stent. It was machined using our aeroPULSE FS50 laser using a single pass.

The laser beam was delivered using a commercially available processing head with an axial jet with a suitable cover gas to suppress oxidation and manage the generated plasma.

The results were an excellent simulation of the feature size and typical thickness of stents. The side walls are less than 65 µm and the feature sizes are <300 µm.