Cutting Mill PULVERISETTE 15

The FRITSCH Cutting Mill PULVERISETTE 15 is ideal for the comminution of dry sample materials with soft to medium-hard consistency, for fibrous materials or cellulosic materials, as well as for sample preparation according to RoHS with a feed size of 70 x 70 mm and a throughput quantity of up to 50l/h. A cutting rotor speed of up to 3400 rpm ensures a high air throughput, fast processing and reproducible results.

The simple FRITSCH cleaning makes your work much easier.

In Cutting Mills, the sample is comminuted according to the cutting principle of scissors, increasingly fine between the knives of the rotor and fixed knives until the desired final fineness is achieved.

Unique grinding chamber geometry: The grinding chamber is designed with minimal dead space and progressive cutting geometry between rotor and fixed knives. The sample material is continuously moved during comminution and cannot settle anywhere. In conjunctions with the special air flow, this is the basis for swift, blockage-free operation and fast cleaning without residue.

Cutting Mill PULVERISETTE 15

Features

- Fast, reproducible size reduction due to high cutting rotor speed of up to 3400 rpm

- Max. feed size 70 x 70 mm

- Throughput quantity of up to 50 l/h

- Defined final fineness replaceable sieve inserts 0.25 – 20 mm, (further sieve sizes available)

- Collecting vessel 3.5 litres or 60 litres

- Funnel for long- and bulk solids or protected funnel made of stainless steel with plastic sample pusher

- Housing and closing lid can be lifted to open completely – lid completely removable

- Externally adjustable cutting gap

- Rotor knives can be turned (2 cutting edges) – double service life

- Very stable: the rotor with double bearing on shaft and in the lid.

- Especially easy FRITSCH cleaning

- Optimum airflow for particularly fast size reduction and secure protection against clogging

- Extensive accessories for simplifying your daily work

specifications

| Working principle | cutting |

|---|---|

| Optimal for material type | medium-hard, soft, fibrous samples |

| Cutting tools | rotor with straight cutting edges and fixed knives |

| Materials of the cutting tools | tool steel, stainless steel 316L, chromium-free tool steel, chromium-free steel DC01 |

| Max. feed size (depends on material and funnel) | 70 x 70 mm |

| Max. throughput (depending on the material and sieve size) | 50 l/h |

| Final fineness (depends on sieve cassette – additional sieve sizes available) | 0.25 – 20 mm |

| Feeding | batchwise/continuous |

| Rotor speed | 2800/3400 rpm* |

| Rotor peripheral speed | 14.92/17.9 m/s* |

| Drive | Up to 2.1 kW three-phase motor or single phase motor |

| Electrical Details | 400 V/3~, 50 Hz, 1790 watt, 5.5 Nm

200-240 V/1~, 50 Hz, 2150 watt, 4.8 Nm 200 V/3~, 60 Hz, 2140 watt, 5.5 Nm 100-120 V/1~, 60 Hz, 1900 watt, 3 Nm |

| Emission sound pressure level at the workplace according to DIN EN ISO 3746 (depending on the material to be ground, rotor and sieve insert used) | LpAd = 78 dB |

| Weight | 32 kg |

| Dimensions (W x D x H) | table-mounting or on stand 42 x 48 x 69 cm |

The PULVERISETTE 15 with voltage of “/3~” can only be operated on a three-phase supply network.

The three-phase version “/3~” is definitely preferable instead of a single-phase version “/1~”, because the three-phase version obtains more power, better effectiveness and greater energy efficiency.

Manufacturers

show DATA — DO NOT CHANGE ID–

Industries

show DATA — DO NOT CHANGE ID–

Methods

show DATA — DO NOT CHANGE ID–

Spares and accessories for Cutting Mill PULVERISETTE 15

ACCESSORIES FOR CHROMIUM-FREE COMMINUTION

When chromium-free size reduction is required for sample preparation according to RoHS – for example for verification of hexavalent chromium – or for XRF analysis. FRITSCH cutting tool sets of chromium-free tool steel and sieve cassettes made of chromium-free steel DC01 offer absolute assurance.

SIEVE INSERTS MADE OF STAINLESS STEEL 316L

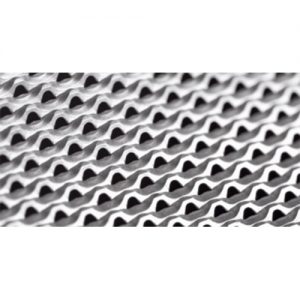

Sieve inserts determine the final fineness of a sample. Sieve inserts with trapezoidal and square perforations are offered. Sieve inserts with trapezoidal perforations improve size reduction through extra shearing action. Sieve inserts with square perforations are used for the grinding of brittle materials and materials of medium fineness with a narrow grain band.

Sieve inserts are also available in further perforations.