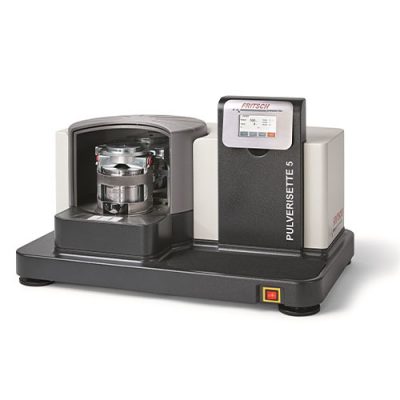

Planetary Mill Pulverisette 5 premium line

FRITSCH Planetary Ball Mills – high-performance all-rounder in routine laboratory work

The Planetary Mill PULVERISETTE 5 premium line with 2 grinding stations is the ideal mill for fast wet and dry grinding of hard, medium-hard, soft, brittle and moist samples as well as for mechanical alloying, mixing and homogenising of larger sample quantities with reliable results down into the nano range – and an absolutely secure automatic clamping of the grinding bowls.

The comminution takes place primarily through the high-energy impact of grinding balls and partially through friction between grinding balls and the grinding bowl wall. To achieve this, the grinding bowl, containing the material to be ground and grinding balls, rotates around its own axis on a main disk rotating in the opposite direction. At a certain speed, the centrifugal force causes the ground sample material and grinding balls to bounce off the inner wall of the grinding bowl, cross the bowl diagonally at an extremely high speed and impact the material to be ground on the opposite wall of the bowl. The grinding bowls reach twice the speed of the main disk during this process.

Due to the extra strong 2.2 kW drive power and centrifugal acceleration up to 64 g and up to 800 rpm (rotational speed of the bowl 1,600 rpm) are high-performance grindings down into the nano range possible.

Planetary Mill Pulverisette 5 premium line

Features

- Extra strong 2.2 kW drive power and extremely high centrifugal acceleration up to 64 g and up to 800 rpm (rotational speed of the bowl 1,600 rpm)

- Maximum operational safety due to ServoLOCK clamping of the grinding bowls

- Blocking of the mill in the event of impermissible operating states

- Automatic shutoff function if an imbalance occurs

- Reliable bowl detection via RFID chip and optimization of grinding speeds via RFID-Chip

- Safely guided insertion of grinding bowls

- Safe opening in the event of overpressure

- Intuitive touchscreen operation with colour display

- Simultaneous processing of up to 4 samples

- Useful capacity up to 2 x 225 ml

- Up to 8 programmes can be saved, software MillControl (optional), USB inter face for transmission of process parameters

- Extensive accessories for simplifying your daily work

specifications

| Working principle | impact force |

|---|---|

| Optimal for material type | hard, medium-hard, soft, brittle, tough, moist |

| Number of grinding stations | 2 |

| Grinding tools | grinding bowls and grinding balls |

| Materials of the grinding tools | agate, zirconium oxide, hardened stainless steel, hardmetal tungsten carbide |

| Grinding bowl sizes | 125, 150, 250, 420, 500 ml |

| Grinding ball diameter | 0.1 – 20 mm |

| Max. feed size (depends on material) | 10 mm |

| Min. sample quantity | 15 ml |

| Max. sample quantity | 450 ml |

| Final fineness (depends on material) | <0.1 µm |

| Typical grinding time down to analytical fineness | 3 min |

| Grinding process | wet and dry |

| Grinding in inert gas | yes |

| Gas pressure and temperature measurement | yes |

| Rotational speed of main disk | 100-800 rpm |

| Transmission ratio planetary disk / grinding bowl | i relative = 1 : -2 |

| Effective diameter of main disk | 180 mm |

| Centrifugal acceleration (g = 9.81 m/s²) | 64 g |

| Interfaces | yes |

| Electrical Details, additional voltages available upon request | 200-240 V/1~, 50-60 Hz, 2800 watt |

| Emission sound pressure level at the workplace according to DIN EN ISO 3746 (depending on the material to be ground, grinding bowls/balls, selected rotational speed) | approx. LpAd = 84 dB |

| Weight | 110 kg |

| Dimensions (W x D x H) | bench top instrument 82 x 52 x 48 cm |

Manufacturers

show DATA — DO NOT CHANGE ID–

Industries

show DATA — DO NOT CHANGE ID–

Methods

show DATA — DO NOT CHANGE ID–

Spares and accessories for PULVERISETTE 5 (premium line)

GRINDING BOWLS

Please select 2 grinding bowls offered in the sizes 500 ml, 420 ml, 250 ml, 150 ml and 125 ml to perfectly match your sample volume. The useful capacity of the grinding bowls can be found in the selection aid. All grinding bowls of the FRITSCH premium line are cased in stainless steel, have a label and the same inner diameter regardless of their volume.

For the best grinding results in each individual case, all grinding bowls are available in 4 different materials, thus directly preventing contamination of the samples as a result of undesired abrasion.

KF-Win software enables your PC to control KEM’s Karl Fischer Moisture Titrators,

MKV-710B, MKC-710B, MKC-520, MKA-520, MKS-520, MKC-510N, MKA-510N or MKS-510N.

When it is connected to MKV-710B or MKC-710B, the functions equivalent to MKV-710M or MKC-710M will be available.

GRINDING BALLS

For achieving best grinding results grinding balls are available in 0.1 – 20 mm diameters and in different materials, thus directly preventing contamination of the samples as a result of undesired abrasion. The recommended number of balls per grinding bowl can be found in the selection aid.

SPECIAL ACCESSORIES

The software MillControl enables the automatic control of the Planetary Mill PULVERISETTE 5 premium line and validation of the grinding process. The actual rotational speed and power consumption are checked and documented. With the utilization of 2 EASY GTM grinding bowls with special lid and transmitter you turn your PULVERISETTE 5 premium line into an analytical measuring system for visualizing pressure and temperature during the grinding process.

For quickly and safely grinding in inert gas and for mechanical alloying premium line gassing lids are recommended.

A certificate for IQ/OQ documentation is also available.