Many coating are still measured by exposing them for months with salt spray. The Rapid Electrochemical Assessment of Paint (REAP) allows within 24 hours to determine the Time To Failure (TTF) by combining different techniques.

Rapid is a relative term. This procedure includes an overnight step, which, for the common spectroscopist, will seem like a long time, but for a corrosion scientist, it is a rather short amount of time. During this protocol, a series of measurements with multiple samples is performed, and long-term stability is extrapolated. Electrochemical Impedance Spectroscopy (EIS) and cathodic disbonding are the central techniques for the Rapid Electrochemical Assessment of Paint (REAP), which allows an estimation of the time to failure.

The REAP procedure is not a casual recommendation, but a robust and well-established method. It adheres to the stringent standards of the ASTM G01.11 subcommittee on Electrochemical Measurements in Corrosion. The original proposal for REAP was published in Kending et al, J. Coatings Tech., 1996, 68, p. 39 – 47, a highly regarded source accessible through Research Gate.

During this procedure, the corrosion pote the ASTM G01.11 subcommittee on Electrochemical Measurements in Corrosion terminated. These three parameters can be used initially suggested by Kending et al. regarding the REAP; both samples should have a cured and dried coating. For the meaThis procedure will determine the corrosion potential, the coating’s water uptake, and the disbonding rateor 24 h.

For the REAP procedure, it’s essential to have pairs of samples or an even number of samples. A minimum of three measurements is typically recommended. Half of the samples are kept pristine, while the other half is scribed. The scribed samples should have a right angle cross with both lines measuring 2 cm in length. To ensure adherence to the ASTM standards, you can refer to the guidelines on how to scribe a sample in ASTM B117.

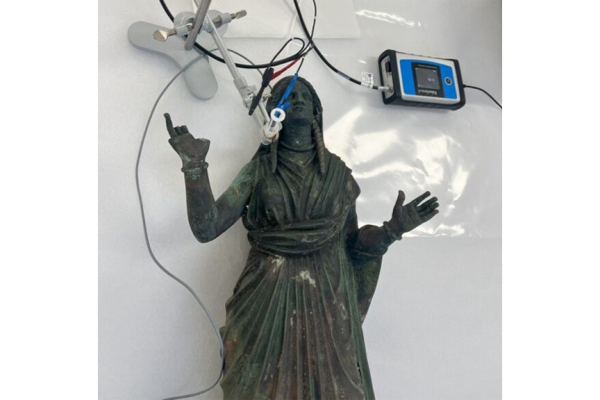

You will also need to expose a defined area of the sample to the measuring solution and have it connected to your potentiostat.

There is a step-by-step manual for the REAP, which should enable you to perform the REAP:

1- Corrosion Potential:

The first parameter that needs to be determined is the corrosion potential Ecorr of the pristine sample, because it is needed for the following measurements. The Ecorr should be measured in a short time after the samples immersion, so we recommend setting up the measurement parameters first before pouring the measurement solution (0.5 M NaCl) into the cell. A Corrosion Potential (also known as Open Circuit Potentiometry) is performed with 200 s and one value every 0.5 s.

2- Determine the Coatings Capacity without Swelling:

The goal of this step is to determine the capacity of the pristine sample’s coating. Later the coatings capacity after immersion in water for 24 h will be determined. The change in the capacity is caused by water penetrating the coating. With the two capacities the water uptake can be calculated.

The reference and counter electrode as well as the sample should still be connected from step 1.

3- Disbonding Rate:

During disbonding the coating peels of the substrate. The goal of this step is to find the disbonding rate of the coating. This will be measured in distance from the initial scratch per time dx/dt, so how fast does the disbonded area expand.

A proper coating won’t allow disbonding, so we need to use the scribed sample. The pristine sample stays in the NaCl solution for 24 hours, to perform later step 4, so you will need a second setup or at least holder and vessel to keep the sample immersed in the NaCl solution.

The scribed sample would still disbond rather slowly, so this process is accelerated by applying a potential to the scribed samples for 24 h while the sample is immersed in NaCl solution. This potential is very cathodic, so hydrogen will form during the time under this potential. This should increase the rate of disbonding, so the disbonding rate can be evaluated within 24 h.

4- Determine the Coatings Capacity with Swelling:

The pristine sample’s coating will have taken up some water, after the 24 h of immersion in the NaCl solution. To determine this water uptake the coating capacity needs to be determined. This is possible because the water has a very different dielectric constant than the organic compounds in the coating.

The measurement is done similarly to the measurement from step 2. First, the cell with the pristine sample is connected (reference, counter, and working electrode). Then the EIS measurement from step 2 is repeated.

5- Determine Rcorr:

From the fit in step 4 also the corrosion resistance Rcorr, labeled as Rct, can be extrapolated. Just read the value from the fit of the EIS after the 24 h of immersion.

6- Estimation of the Time To Failure (TTF):

The TTF can be calculated if the corrosion resistance Rcorr, the water uptake in %V and the disbonding rate dx/dt are known.