The role of coatings in food storage containers, or any surface that comes into contact with food, is crucial. These coatings serve a dual purpose: they prevent food spoilage and contamination, and they shield the container from the corrosive properties of the food. Tins, for instance, are a popular choice for food storage due to their ability to protect food from air and light for extended periods. Moreover, tins, being conducting surfaces, allow for in-depth electrochemical studies of both themselves and their coatings.

While it would be ideal to predict the expiration date of food stored in a container, this is not always straightforward. The varying reaction rates of the food’s spoiling components, which are not always constant, pose a significant challenge. These rates can be linear or parabolic. Additionally, the storage temperature can vary, especially if the food is exported to different countries, further complicating the prediction process.

As we’ve discussed in previous sections, a high polarization resistance or the resistance added by the coating indicates a low corrosion of the can. This, in turn, translates to a longer shelf life for the food stored in it. However, it’s important to note that the resistance of the coating is not a static value. It is influenced by factors such as temperature and storage time. Therefore, to accurately predict the shelf life, it’s necessary to conduct measurements at various temperatures and storage times.

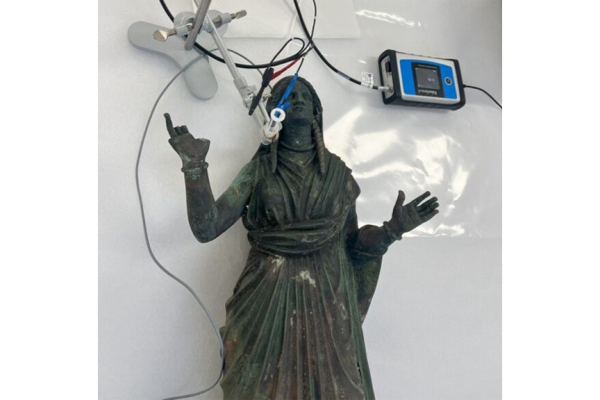

EIS, a nondestructive technique highly sensitive to interface changes, is a suitable method for investigating coatings for food cans.

Testing the Shelf Life:

First, cans are coated and packed as usual. They are tested after certain time periods, such as 1 day, 1 week, 1 month, 4 months, and 12 months.

If the product in the can is being conducted, the measurement can be performed on the product, which acts as an electrolyte. Otherwise, the product needs to be replaced with 0.5 M NaCl solution. Keep in mind that a fat or oil film on the can coating might act as an additional film, but strong detergents to remove the fat film may also change your coating.

The can is connected as the working electrode. The reference and counter electrodes are immersed in the can’s solution. Electrochemical Impedance Spectroscopy is performed, and the spectra for the different storage times are compared.

Coating Research in Food Industry

Coating, contamination storage, corrosion, counter electrode, detergent, disbonding, Electrochemical Impedance Spectroscopy (EIS), Electrochemistry, equivalent circuit, expiration date, food can, Food Industry, food storage containers, polarization resistance, shelf life, spoiling substance, working electrode

Related Posts

Recent Comments

Archives

- February 2026

- December 2025

- October 2025

- September 2025

- August 2025

- July 2025

- April 2025

- July 2024

- June 2024

- January 2024

- October 2023

- September 2023

- July 2023

- May 2023

- February 2023

- January 2023

- November 2022

- September 2022

- August 2022

- July 2022

- June 2022

- May 2022

- April 2022

- March 2022

- February 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021

- April 2021

- March 2021

- February 2021

- January 2021

- December 2020

- November 2020

- October 2020

- September 2020

- August 2020

- July 2020

- June 2020

- May 2020

- April 2020

- March 2020

- April 2019

- March 2019

Categories

Recent Posts

- NWSPEC GC 6890 February 4, 2026

- NWSPEC HPLC 6000 UV-VIS: Cost-Effective, Reliable, and Compliant February 4, 2026

- ISO 13485 Certification Awarded to Ocean Optics, Highlighting Commitment to Quality and Safety December 8, 2025

- New PalmSens Potentiostat with integrated multiplexer in One: The EmStat4 MUX October 8, 2025

Tags

AFIDA

ANALYSETTE 22

ASTM D4054

Aviation

Bionanoparticles

Certification

Compliance

corrosion measurements

Electrochemical Impedance Spectroscopy (EIS)

Electrochemical Techniques

Electrochemistry

Exosomes

Galvanostat

High_Resolution_spectrometers

Impedance Analyzer

Impedance Spectroscopy

ISO 13485

Mechanical Tests

Medical Instrumentation

Modular Spectroscopy

Nexus

NIR Spectroscopy

Ocean-Optics

Ocean_Insight

Ocean_Optics

PalmSens

PalmSense

Pharmaceutical

Pharmaceutical Waste

Polymer-based aqueous Column

Potentiostat

Quality Assurance

Quality Management System

Regulatory Standards

Sample Preparation

Search Publication

SEC Column

Shodex

spectrometer

Spectroscopy application

Spectroscopy Equipment

Stanhope Seta

UB-50

UB-100

Viruses